Endless Configurations. Simple Interface.

The SampleStream Platform is brought to life by the seamless interplay of several different software packages. A unique plugin system enables the SampleStream Pump Box and Flow Cell Modules to be controlled directly by the PAL 3 System itself. With the activities of the SampleStream modules controlled directly via the PAL 3 System, existing drivers for the PAL 3 System enable direct control of the entire platform from within many popular data acquisition applications. All of this is animated via scripted methods that glue all of this functionality together. Taken together, this architecture makes it simple to assemble complex workflows in bite-sized chunks that are executed in the software platforms you and your scientists are running today. Read about each component in more detail below.

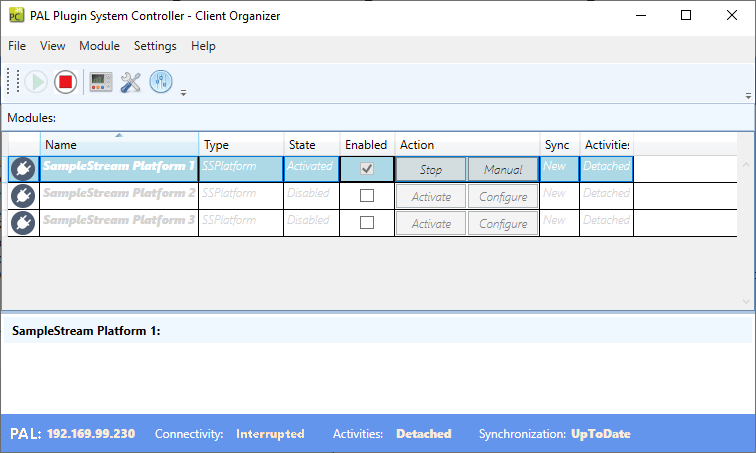

The Plugin System

The Plugin System is truly remarkable. It enables nearly any piece of hardware or software that has an automation interface to be controlled directly by the PAL 3 System. That means that the PAL 3 System serves as a central point of workflow integration for multiple pieces of hardware. It also means that adding throughput to your SampleStream Platform is as simple as duplicating the Flow Cell and Pump Box modules on the PAL 3 System and configuring a second copy of the plugin.

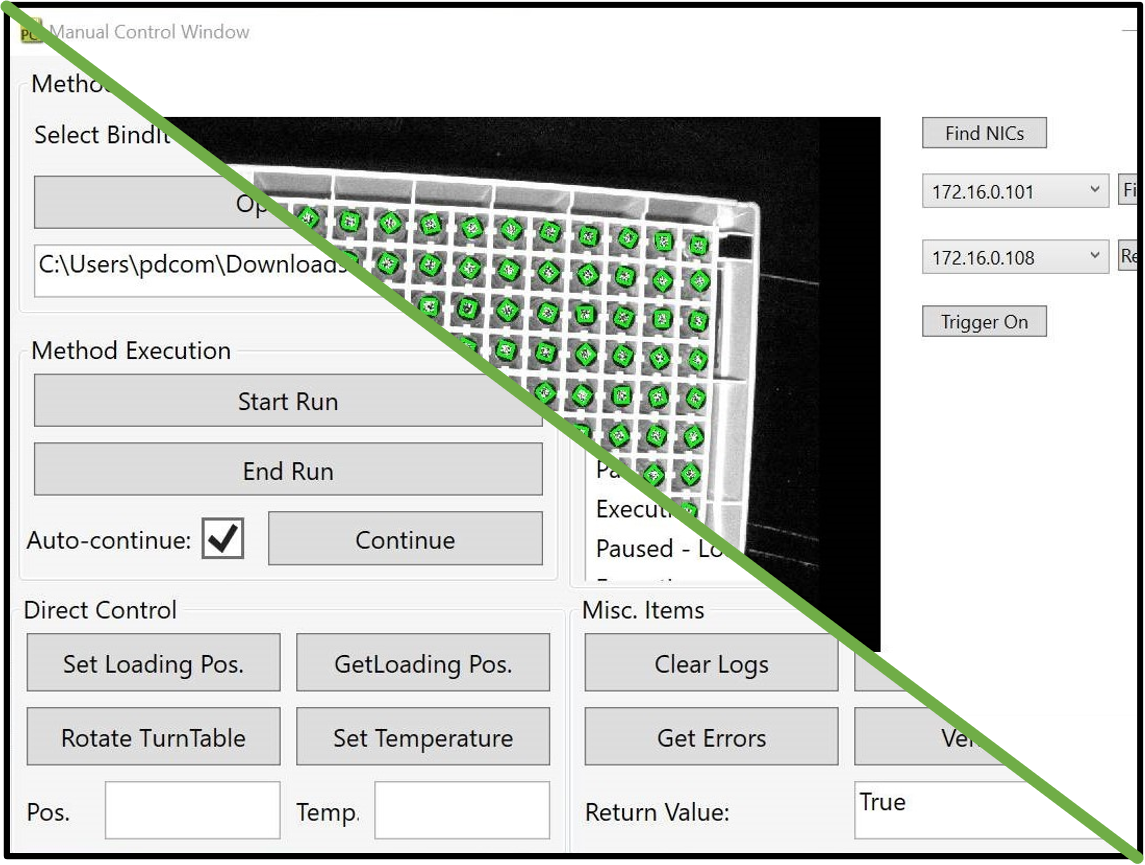

Third-Party Hardware

If it has an automation interface, it can have a plugin. Here, plugins have been created for a barcode reader (upper right) and a popular automation platform for magnetic bead-based purifications (lower left). Just like the SampleStream modules, these additional components can be controlled as part of a combined method. However, plugins are not limited to hardware, they can also be used to integrate software for data acquisition or processing to create truly sample-to-answer workflows.

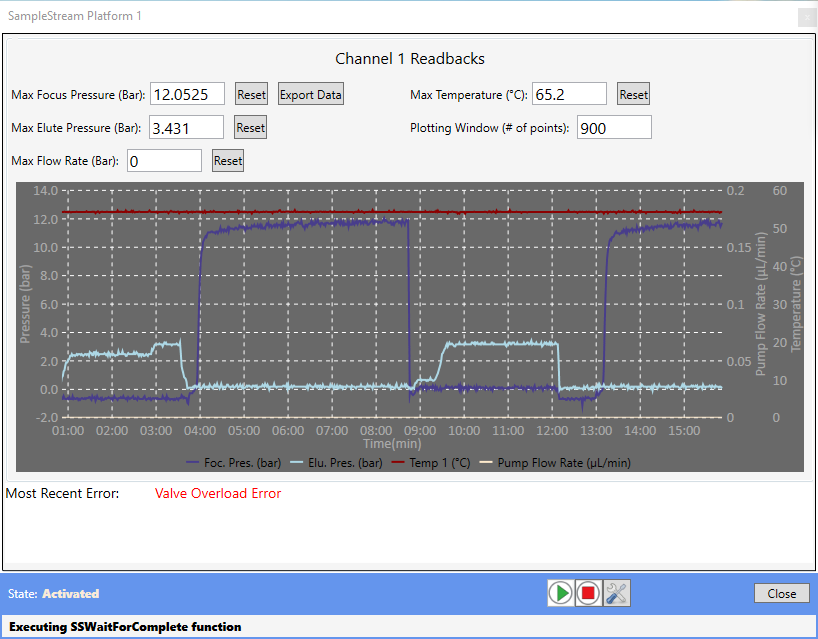

The SampleStream Plugin

The SampleStream Plugin not only enables control of the platform from user methods, it is also the interface for direct control and monitoring of the system. Providing real-time information from pressure transducers, temperature probes, RFID readers and more, the full-featured plugin gives the user all of the controls and information needed for operation in a convenient package.

System Monitoring

The Status window of the plugin provides real-time graphing of the pressures and temperature in the flow cell and records the maximum values of these parameters that have been observed during operation. Channel pressure is measured both above and below the membrane, enabling users to select maximum and minimum pressures for automatic shutdown during focusing and elution as well as monitor transmembrane pressure and the back pressure created by any downstream components, such as an electrospray ionization source. Rest assured that a plugged emitter will never again cause the loss of your precious samples.

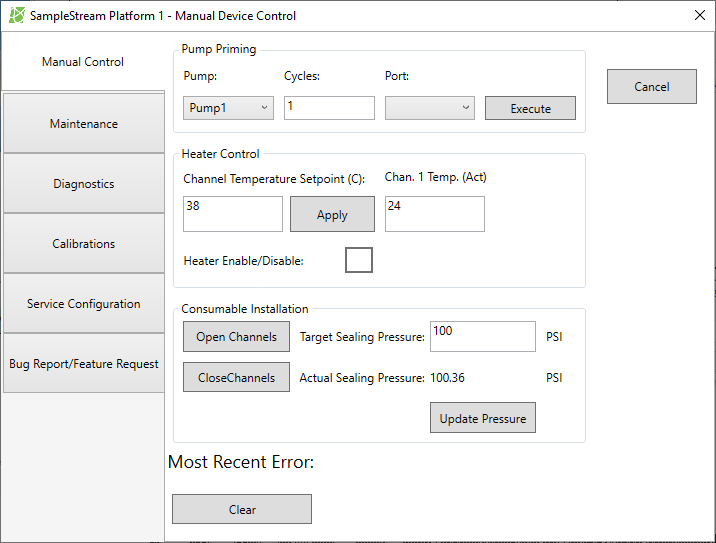

Manual Control

The Manual Control window presents users all of the features needed to operate, maintain, diagnose and calibrate the SampleStream platform. Pump priming, temperature control, consumable installation, pressure transducer calibration, leak checking and more can all be accomplished via the Manual Control window.

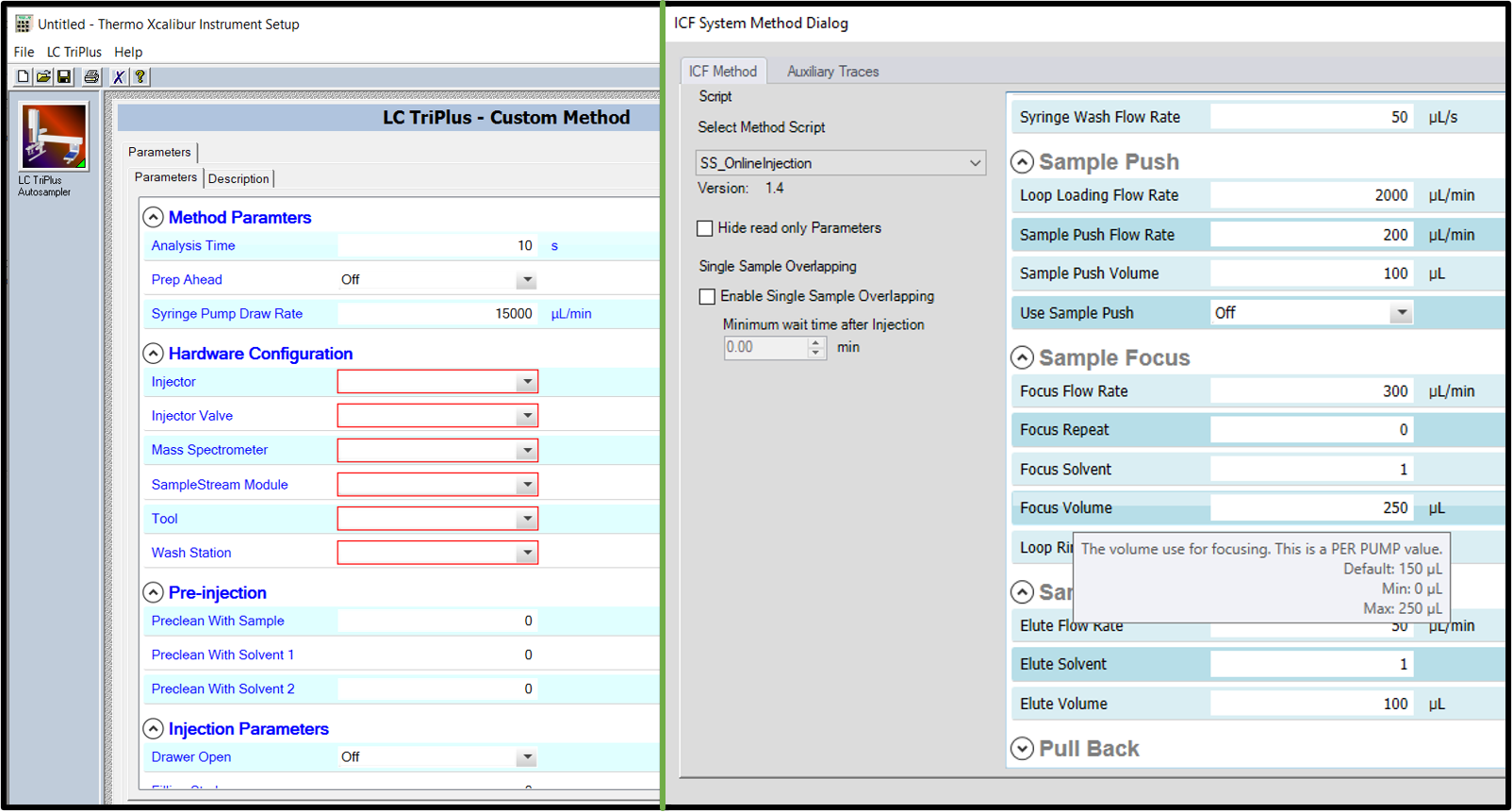

Data Acquisition

If you have ever acquired data with an LC-MS system, using the SampleStream Platform will be a breeze. Vendor-specific drivers for software like Xcalibur™, HyStar™ and more enable direct integration into method editing and sequence/run list creation. Simply load a script, set the appropriate parameters in the interface, and you’re done. If you get stuck, helpful tool tips provide extended descriptions of method parameters as well as minimum, maximum and default values for each so you’ll always be in the know. Also, this method creation interface is common across acquisition software packages, making it easy to integrate SampleStream with different vendor hardware, even within the same lab.

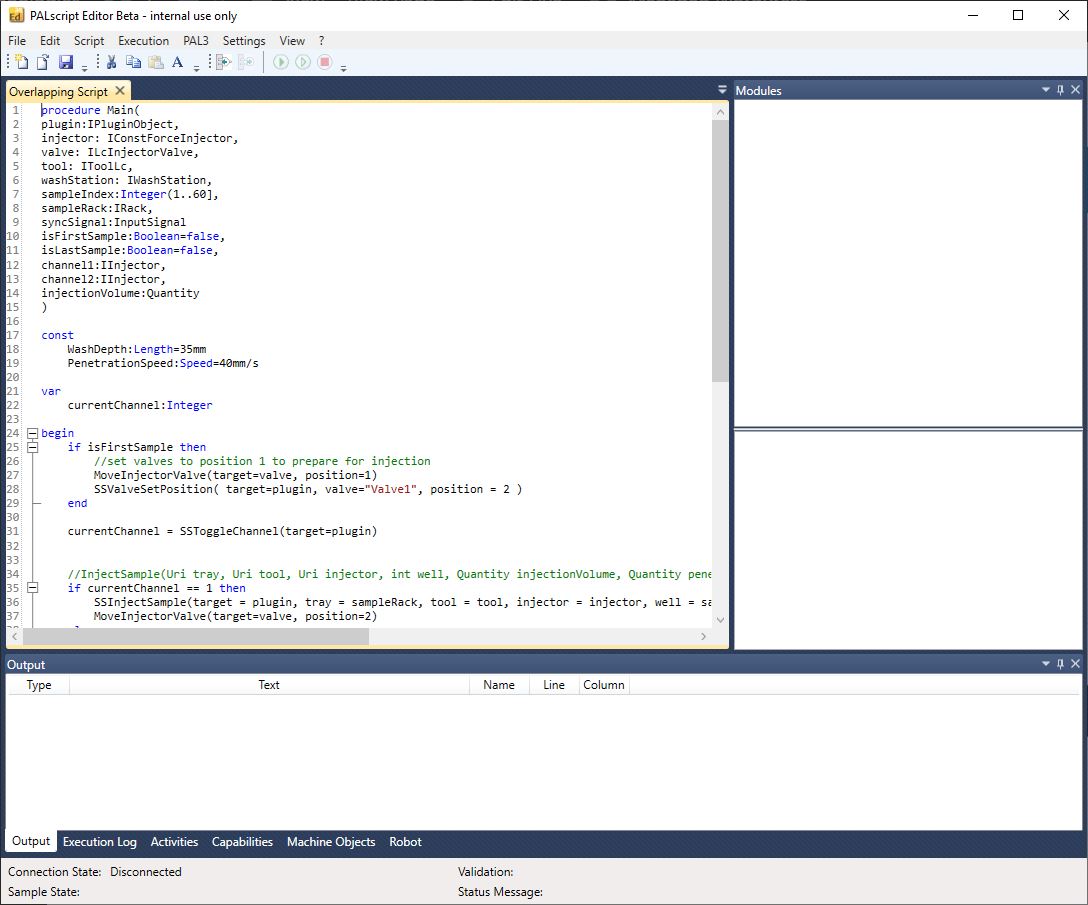

Custom Scripting

The integrated SampleStream Platform is commanded by a powerful and flexible scripting language, enabling IPT to provide bespoke solutions that address even the most complex analytical requirements. With features like bubble detection, clogged valve detection, solvent switching and more, there are few limits to what is possible.

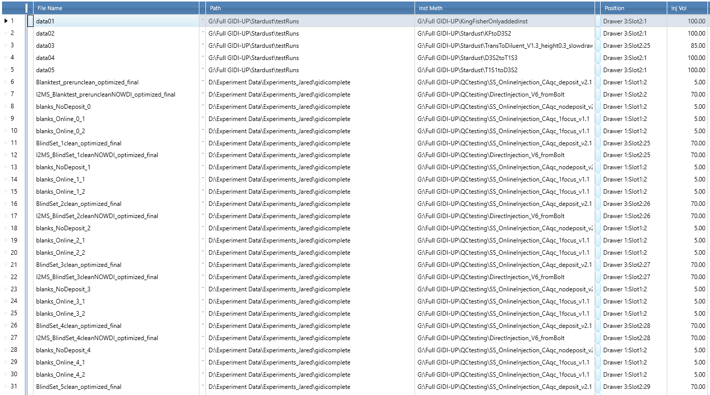

Workflow Integration

With all of this capability, it would be easy to imagine operating such a system would be complicated. However, very complex workflows can be easily sequenced. In the example, row 1 performs an automated pull-down, rows 2-4 perform various plate transfers, the remaining rows perform clean-up with SampleStream and direct injection to a detector. While this approach is highly flexible, it is also intuitive.